In the category of "things to which I've given zero thought", the complexity of this topic surprised me - I'll probably never learn much more about it, but some of you may be inspired to do so:

At ArchDaily, José Tomás Franco describes cut patterns that are most frequently used to saw wood into different shapes and sizes.

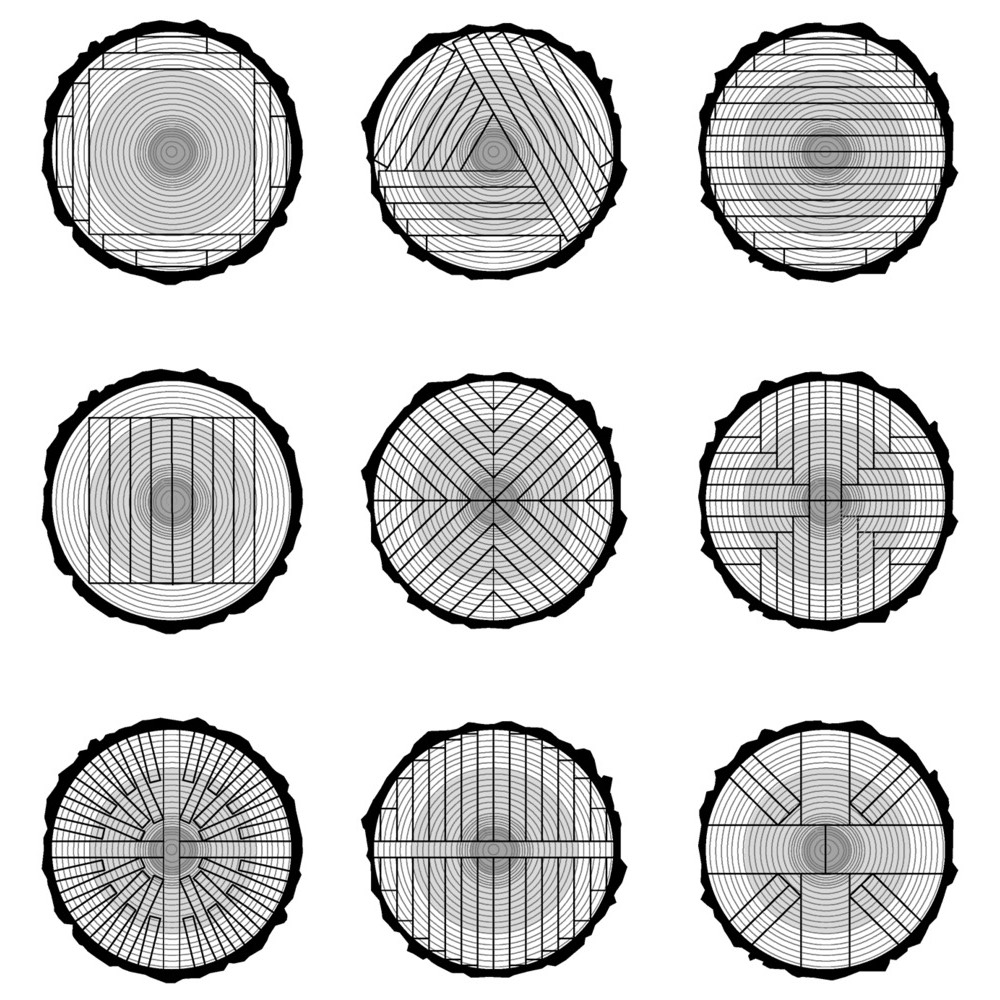

The lumber we use to build is extracted from the trunks of more than 2000 tree species worldwide, each with different densities and humidity levels. In addition to these factors, the way in which the trunk is cut establishes the functionality and final characteristics of each wood section. Let’s review the most-used cuts.

Each cut pattern produces wood with grain patterns and composition that makes it more or less suited to particular uses. For instance, the “interlocked cut” produces thin boards that are “quite resistant to deformation”.

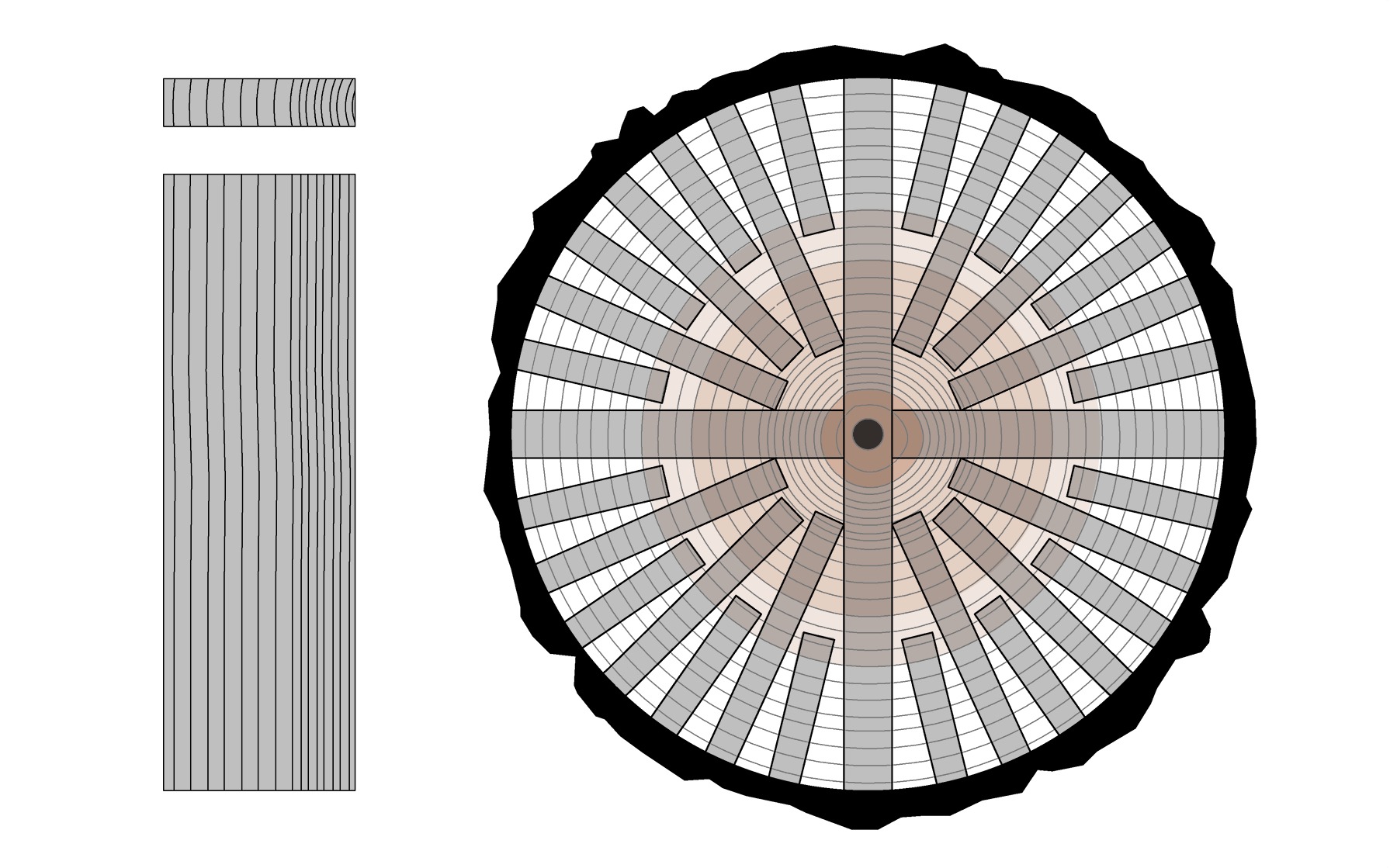

Although these techniques may differ depending on the use required, there are three main ways to cut a log into boards: Rift, Quarter and Flat Sawn- and a series of variations that arise from them:

Rift Sawn

This cut is made perpendicular to the growth rings. It keeps the wood grain visible and avoids warping (deformations in the shape of the board) or fissures (longitudinal cracks), but wastes more material than other cut types.

Quarter Sawn

Cuts are made parallel to the four axes of the trunk, obtaining pieces that are not too prone to warping with a large number of visible rings.

Flat Sawn/Live Sawn

This is a widely used method, although the resulting pieces are not of the best quality since most include a certain percentage of the Sapwood and the Heartwood. The centerpiece that coincides with the core can tend to break, while the remaining pieces are prone to warp and curl.

|

| Rift sawn |

This cut is made perpendicular to the growth rings. It keeps the wood grain visible and avoids warping (deformations in the shape of the board) or fissures (longitudinal cracks), but wastes more material than other cut types.

Quarter Sawn

Cuts are made parallel to the four axes of the trunk, obtaining pieces that are not too prone to warping with a large number of visible rings.

Flat Sawn/Live Sawn

This is a widely used method, although the resulting pieces are not of the best quality since most include a certain percentage of the Sapwood and the Heartwood. The centerpiece that coincides with the core can tend to break, while the remaining pieces are prone to warp and curl.

Much more at Arch Daily, via Kottke.

No comments:

Post a Comment